Nowadays, Hydraulic lifts play an important role in our lives.

As you can see, Hydraulic lifts are potent machines used for lifting or holding heavy loads. They are used at construction sites and many other industrial areas as well as in vehicles. I guess we are all aware of this. Now, we’ll explore hydraulic lifts’ functioning as well as their hydraulic lift uses, benefits, and safety concerns.

The aim is to make a Hydraulic Lift model.

First, we have to know about Hydraulics. So, let’s begin with it.

What is Hydraulics?

Hydraulics is the study of liquids and their mechanical properties. For example, how they move, refuse movement, and so on In engineering, there is an application using liquids such as water and oil to move things.

How does a Hydraulic lift work?

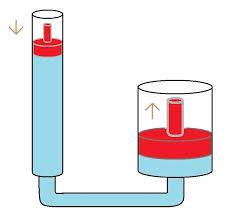

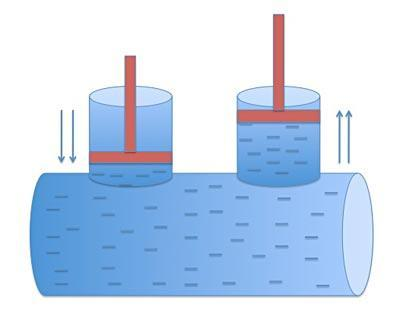

What is hydraulic lift: A hydraulic lift has two components The first is a fluid-filled cylinder, and the second is a piston. When force is applied to the piston, it pushes the fluid into the cylinder, causing an increment in pressure. This pressure is transmitted to another piston, which lifts the load.

Applications of Hydraulic Lifts:

Hydraulic lifts have a wide range of applications and are used in various industries. Some of them are:

- Automotive Industries: Hydraulic lifts are used in car repair shops, car washing stations, and vehicle assembly lines for lifting vehicles.

- Construction Sites:- They are used for lifting heavy construction materials and types of equipment.

- Warehouses:- Movement of goods and pallets on different levels.

- Commercial Buildings:- Provides accessibilities in shopping malls, offices, and hotels.

- Hospitals:- For patient transportation and transferring if there is any patient who has mobility issues.

Advantages of Hydraulic Lifts:

Hydraulic lifts offer many advantages, as follows:-

- High-Lifting Capacity: Hydraulic lift handles heavy loads.

- It is smooth and has control over the lifting process.

- Compact Design: Hydraulic lifts have a compact design and require minimal space.

- Versatile: They can be customized to meet requirements.

- Reliability: Hydraulic lifts are known for their durability, and long lifespan if they are maintained well.

Safety measures for Hydraulic Lifts:

While hydraulic lifts are efficient and reliable, safety should always be a top priority. Here are some essential safety measures:

- A Hydraulic lift needs proper maintenance. So, routine inspections and maintenance should be performed.

- Operators should be properly trained before working with hydraulic lifts.

- Do not overload, hence, weight should be checked before uplifting.

- Install safety devices such as emergency stop buttons and limit switches.

Future developments in Hydraulic Lift Technology:

As advancement in technology continues, hydraulic lift technology is also evolving.

- Energy Efficiency:-For reducing power consumption, integration of energy-efficiency components.

- Automation:-Implementation of an advanced automation system that enhances efficiency.

- Remote monitoring:-Integration of technologies to enable remote monitoring.

- Enhanced safety measures:-Addition the smart sensor for better operational safety.

As we’re aware of hydraulic lift uses, surely now is the best time to do this activity of making Hydraulic lifts. So, let’s take a breath, and we should start a great journey of making an amazing model and learning about it.

This activity is best suited for kids in 7th and 8th grades.

Read Also:

1. Online Coding Classes for Kids

2. Robotics for Kids

3. AI for Kids

Let’s start making your Hydraulic Lift

Materials required:

- Jumbo Popsicle sticks (17)

- Wire

- Wooden skewer

- Syringes (2-10 ml)

- Thin Plastic Tubing

- Tape

- Scissor

Procedure:

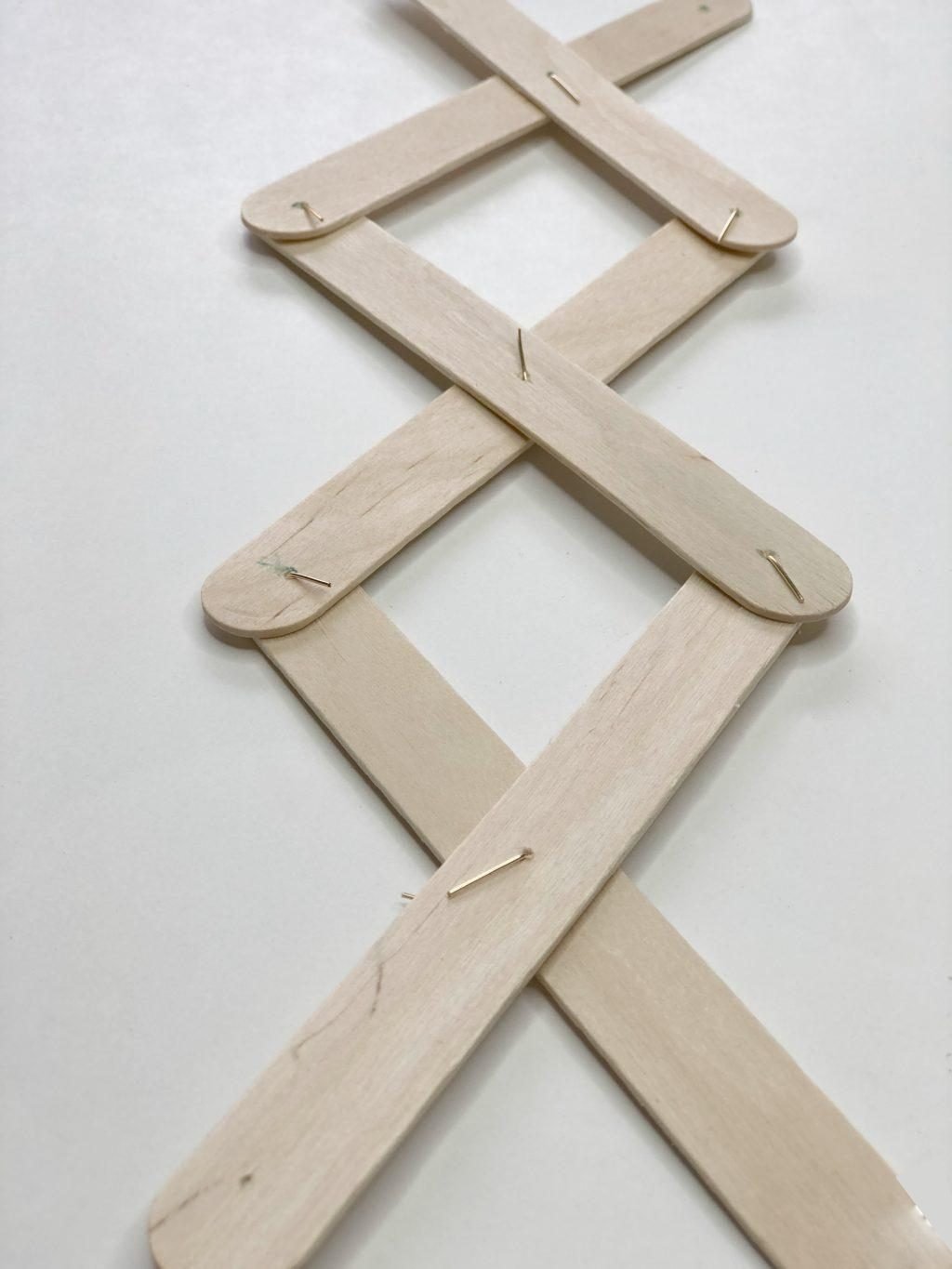

Step 1 – Mark the center and two endpoints on each popsicle stick (1/2 inch). You can draw a hole on the marking points and then match up with other ones

Step 2- Stack the sticks together and tape them with some masking tape.

Step 3- Use a small drill bit and make holes on the marked ends. Be careful, it tends to split and stick to the ends. You can also use a screwdriver, but it takes more time.

Step 4- Once all the sticks have holes, Tie them with wire through the center point. Repeat this three times.

Step 5 – Now, connect the two ends of each pair, and you have three pairs of overlapping sticks.

Step 6 –Repeat the same procedure with the other half. Now you have two moving pieces, each with six sticks.

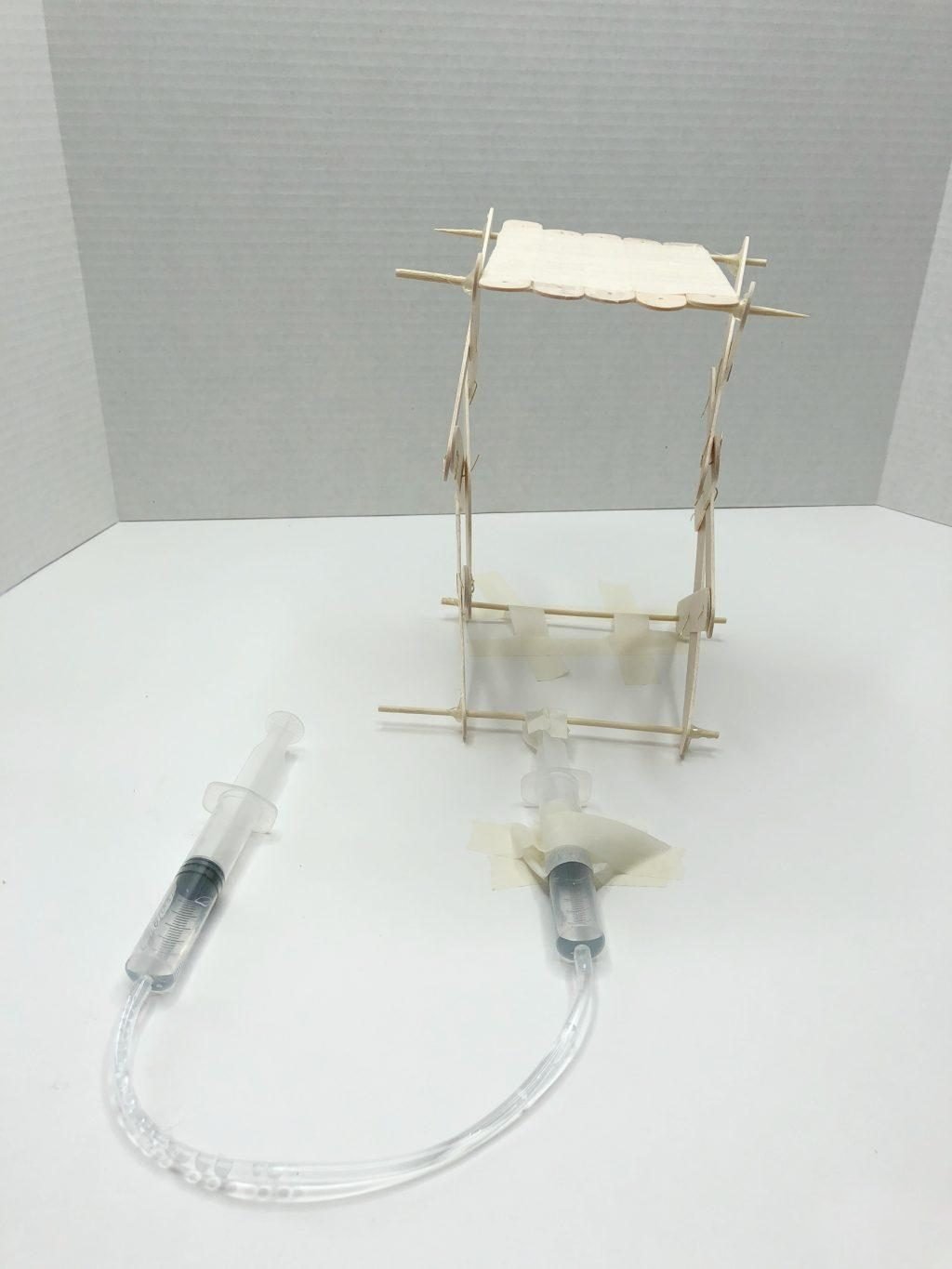

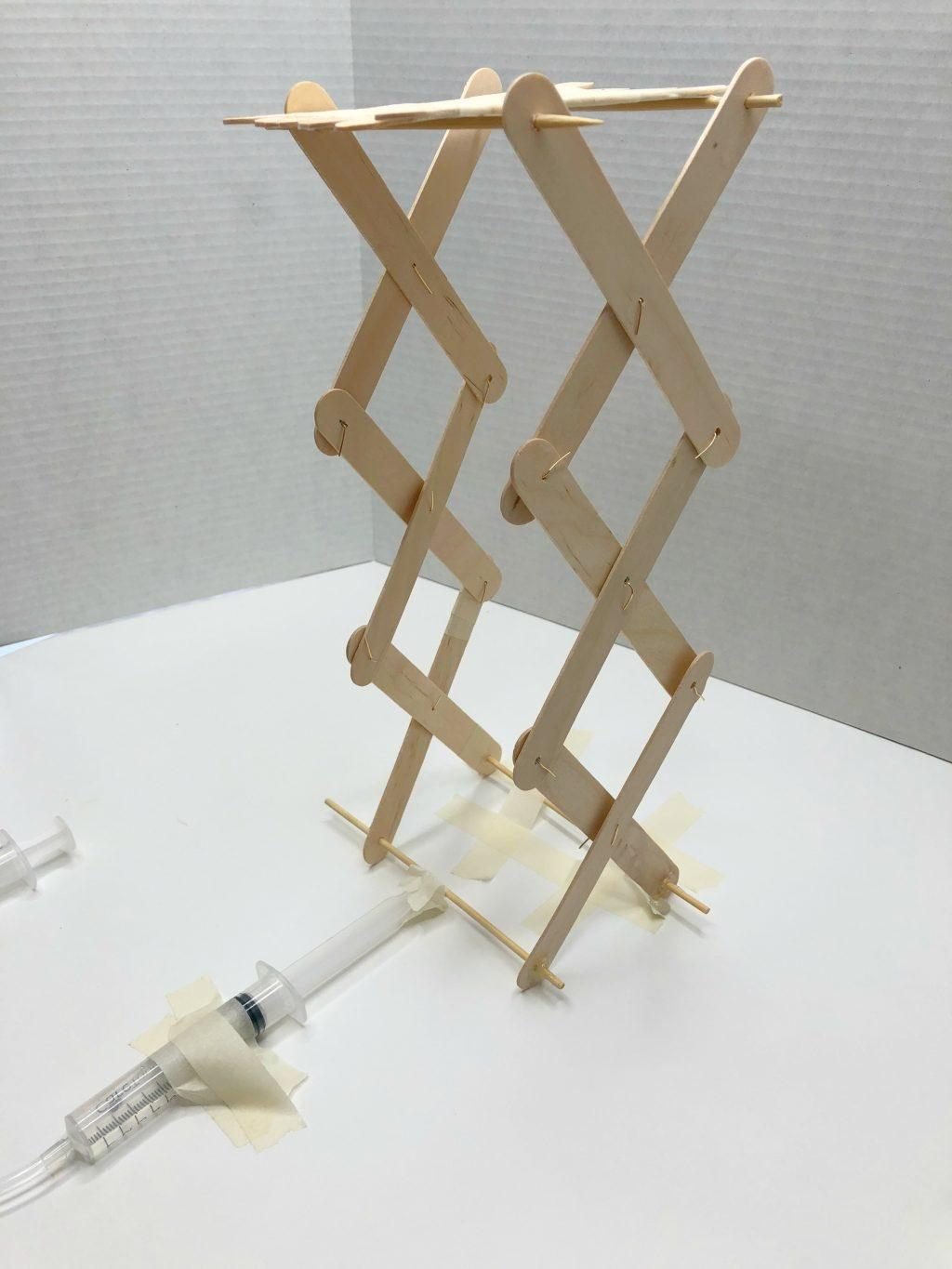

Step 7 –On the bottom and top holes, join the two sides together with a wooden skewer through the holes. You can additionally use glue at the ends so that sticks never slip from their points.

Step 8 –If you want to make a platform for the top of the hydraulic elevator, just tape together six more jumbo sticks.

Step 9 –As per your convenience, tie the bottom surface to the table through tape.

Step 10 –Now, cut a small piece of tubing and attach the syringe at one tip. Then fill the other with water and attach it to the other end of the tube.

Step 11- Once the syringe is prepared, tape one end to the table.

Step 12- Tape the end that slides in and out to the front skewer. Now when you push the syringe in and out, it will lift, and the hydraulic elevator goes down.

But why do we use liquids for moving objects when there is the presence of air for this? Isn’t it a good question?

There is a beautiful answer that, liquid is incompressible. We cannot decrease its volume by pressing on it. For example, if you have a cup filled with marshmallows and you want to add more marshmallows to it, you can compress (squeeze) those marshmallows and add some more to the cup. But if the glass is full of water, then you cannot add more water to the same cup. You cannot squeeze the water. So, if the liquid is incompressible, applying a force at one end of the hydraulic system transfers it to the other end through the Liquid.

Conclusion

Hydraulic lifts have revolutionized various industries by providing a safe and efficient means of lifting heavy objects and people. Their versatility in nature, high lifting capacity, and controlled operation make them indispensable in the construction, warehousing, healthcare, and manufacturing sectors. By focusing on safety measures and conducting regular maintenance, hydraulic lifts can continue to serve as valuable assets for years to come. Also here, we did a great activity over a hydraulic lift. I hope the kids enjoyed this.